Bottle filling capping and labeling machine

Feeding bottles by bottles feeding table --- Automatic Filling products --- Automatic sorting and feeding caps --- Automatic capping caps --- Automatic providing finished products --- Automatic Labeling bottles

SPECIFICATIONS FOR FILLING CAPPING AND LABELING MACHINE | |||

Power: | AC220V 50HZ, Max 1KW | Viscosity: | 1-8000cps |

Air compression: | 0.4-0.6MPa | Temperature: | < 70℃ |

Speed: | 10-120 bpm | Material: | 316L and 304Stainless |

PARTS SUPPLIERS | |||

PLC Control System | Mitsubishi, Japan | Pneumatic element | Hanhae, Korean |

Photoelectric sensor | KEYENCE, Japan | Connection Tube | FDA Food Grade |

Main Features

1. Easy to run. It only take a few minutes to change to fill different filling products.

2. Ensure filling products quality.

3. Automatic Feeding Bottles.

4. Automatic Sorting Caps

5. Automatic Feeding Caps

6. Automatic Capping Caps

7. Automatic Labeling bottles

Detailed Images

Feeding bottles parts:

Worker putting bottles on the Bottles feeding table,then the table will feed the bottles to the conveyor belt.

Star wheel parts:

It feed the bottles in to the filling machine one by one.

This wheel is customized parts.

We need bottle size to confirm the wheel size.

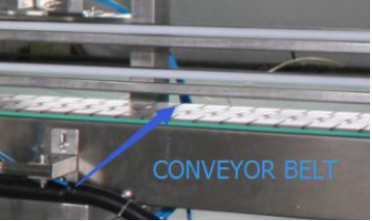

Feeding Parts:

Using conveyor belt for Feeding bottles and it is Frequency control system.

It's stain steel material.

It's for filling machine, labeling machine and sleeve labeling machine.

Sorting caps and Capping parts:

Automatic cap sorting, feeding and capping system for different sizes caps.

This parts can be make according to client's caps' shapes. and it can be 1/2/3... heads capping.

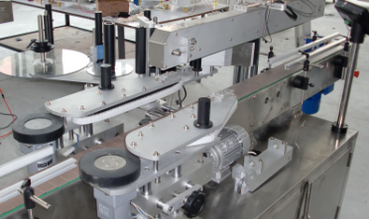

Labeling parts

It is for stick label.

Automatic labeling round bottles, square bottles or other types of bottles. It can be one side labeling, two side labeling and so one.

Shrink sleeve labeling machine:

It is for heat shrink material label.

Automatic labeling round bottles, square bottles and variat bottles.

It can do beer bottle typ, caps sealing type, full bottle type, mineral water type, half bottle type and clean products bottle type.

Our Service

After-sales service:

We guarantee the quality of the main parts within 12 months.If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you.After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site.Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality :

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation:

The seller would dispatch his engineers to instruct the installation. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country).