Main characteristic:

Optional device

Diving function + Self clean function + Heating & Agitating.

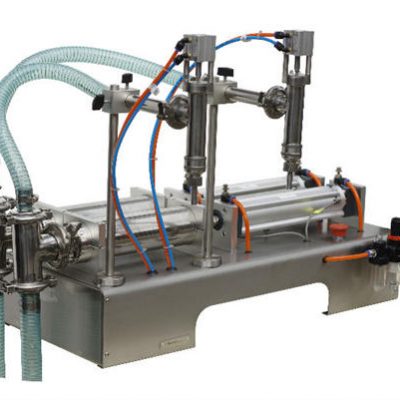

This piston filler is mainly used for viscosity liquid and variety of shape containers in chemical, food, pharmaceutical, oil and other industries. It is composed of piston filler& inside hopper, can be connected with capping, labeling, batch coding and in-line working table to perform a complete production line.

1. Servo ball-screw system applied to drive the piston cylinder, which can fill high viscosity material, such as Oil, Sauce, Honey, Lubricant oil, body lotion, shampoo, etc;

2. According to production, optional to equip Heating & Agitating device inside the hopper to melt & stir evenly the different materials. The max heating temperature is 40 °C. Meanwhile, if filling material is a foamy liquid or the container opening is very small, diving function could be added to aovid overflowing.

3. Machine self-clean function is optional. Use the pneumatic diaphragm pumps draw the clean solvent into filling hopper, by cycle filling to make machine clean.

4. The PLC programmable system and color touch screen to form the control center, automatically adjust filling speed.

5. Stainless steel, non-poisonous & anti-corrosive PTEF hose are applicated for excellent durability and sanitation compliance. Its frame is made of 304 stainless steel and the 316 quality stainless steel used for parts exposed to filling material. The whole machine is designed according to GMP standards.

Technical Parameters

| Filling Nozzles | : 8 heads (cab be selected to 12, 16, 20...) |

| Filling Speed (Tests by 250ml water) | : Approx 1600 BPH (tested by 1.5L dishwashing) Actual production speed will be up & down depends on factors of the head tank height, container opening size, temperatures, etc. |

| Filling Volume | : 100ml ~1500ml : (3L can be achieved by twice filling) |

| Suitable Bottle Size | : Φ 40mm ~ Φ 110mm |

| Voltage | : 3 phase 4 wire, 220V/380V |

| Air Pressure | : 0.55-0.65Mpa |

| Air Consumption | : 0.6 ~ 0.9 m3/min |

| Material | : Stainless Steel 316 & 304 (upon request) |

| Precision | : ≤±1% |

Quick Details

Type: Filling Machine

Condition: New

Application: Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles, Agrochemical, Skincare, Cosmetic

Packaging Type: Barrel, Bottles, Cans, Jars

Packaging Material: Glass, Metal, Plastic, PET, HDP

Automatic Grade: Automatic

Driven Type: Electric

Voltage: 3 phase 4 wire, 220V/380V (Or according to customer voltage requiremen

Power: 4 KW

Place of Origin: Shanghai, China (Mainland)

Brand Name: VKPAK

Dimension(L*W*H): : (L) 2000mm x (W) 1100mm x (H) 1800mm

Weight: : 800 Kg

Certification: ISO9001 & ISO14000

After-sales Service Provided: Engineers available to service machinery overseas

Material: SS 304/ 314 & anti-corrosive PTEF hose