This is a 13 heads linear piston filling machine, especially designed for viscous daily chemical products such detergent shampoo, body lotion, shower gel and so on. Controlled by PLC and touch screen control panel. Accurate measuring, advanced structure, stable operation, and low noise, widely adjusting range and fast filling speed.

1. Adopts advanced mechanical and electrical integration technology. Any filling specification can easily be done by changing parameters in touch screen. Not only the filling volume of 13 filling heads can be changed substantially, but also each filling head volume can be changed finely.

2. With PLC technologies, which make operation of machine steadier, convenient, the human machine interface is friendlier. Photoelectric sensor, approaching switch and other elements are using international famous brand. No bottle no filling, the machine can stop automatically and alarm when bottles get blocked.

3. Various sealing rings used can meet different characteristics of products requirements.

4. Designing and production meet GMP. Easily dismantle, clean and maintain. The parts which contact filling products are made of high quality stainless steel. The machine is safe, environmental, sanitary, adapting to various kinds of working places.

5. The material which contacts liquid will be made of SS304.

6. This machine has the function of “automatic cleaning system” in PLC, can be operated by touch screen.

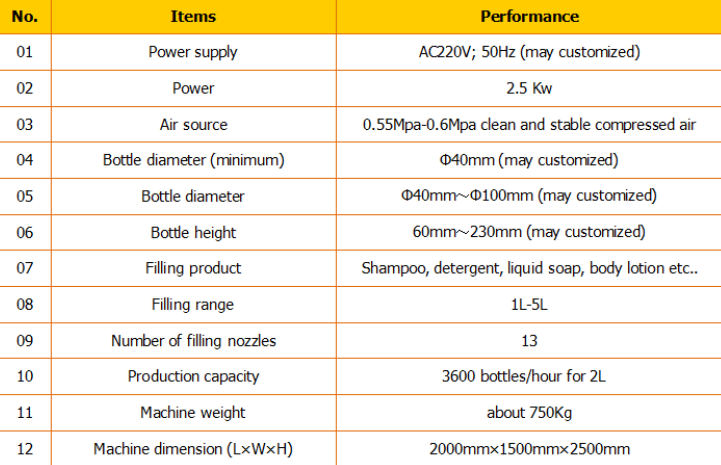

Technical parameter

Machine Parts

1. Filling nozzle

(1) Specification adjustment can be achieved without tool;

(2) The filling pipes are all adopt fast loading clamp, easy to dismantle and maintain.

(3) No dripping.

Main Features

(1) The position of adjustment are all carved scale or equipped with digital display, easy to adjust;

Machine Parts

Part of filling hopper:

(1) The connector is all adopt fast loading clamp type, easily dismantle, clean and maintain.

(2) All pipe joints are installed a drip tight gasket, for avoiding liquid drip, ensured a long-term service life and won’t penetrate.

(3) Designing and production meet GMP. Easily dismantle, clean and maintain.

Main Features

Piston fall off piston cylinder

For the difficulty of cleaning piston cylinder and changing sealing ring, our company designed a new filling machine which adopt fully automatic cleaning system, before clean or replace material, through man-machine interface operation, the piston can automatically fall off and return the piston cylinder, then the rest material will flow into recycling platform by gravity, save the time of manual cleaning.

Quick Details

Type: Filling Machine

Condition: New

Application: Chemical

Packaging Type: Bottles, Cans

Packaging Material: Glass, Plastic

Automatic Grade: Automatic

Driven Type: Electric

Voltage: 220V/380V

Power: 2.5kw

Place of Origin: Shanghai, China (Mainland)

Brand Name: VKPAK

Dimension(L*W*H): 2000X1500X2200

Weight: 800kg

Certification: CE ISO

After-sales Service Provided: Engineers available to service machinery overseas

Filling material: Shampoo

Material: SS316

Capacity: 2000-30000bph

Warranty: 1 Year

Usage: Chemical

Product name: Bottle Automatic Filling Machine

Function: Filling Capping Labeling