Features

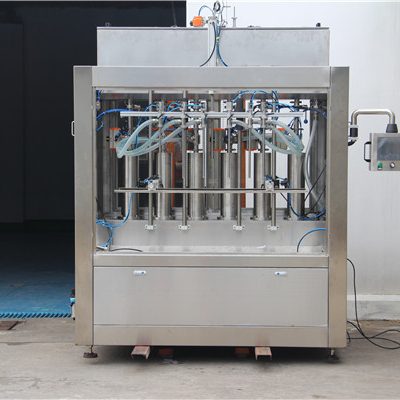

Our automatic gravity filling machinery are ideal machinery to fill water-thick or rich foaming products for the cosmetic, abstersion, and food industries. The filling volume is regulated by controlling the amount of time the product flows at a constant rate through a standard sized tube into the container.

Quality assurance

1. The material of all the parts that the product flows through can be equipped according to the product's character, so the materials are ideal to fill most of strong-corrosive products.

2. The AGF-H series machines are equipped with no-drip and diving nozzles, which make them ideal machines for filling rich foaming and water thick products.

3. Real time adjustability, no bottle no filling, accurate filling volume and a total bottle counter.

4. The AGF filling machines are easy to maintain, no special tools are required.

Product details

| Material | SUS304/316/PP |

| Function | Liquid filling |

| Warranty | 1 year |

| Filling theory | Gravity |

| Production capacity | 20-40BPM |

| Model | AGF |

| Bottle type | Hard PET bottle and glass bottle |

| Filling range | <1000ml |

| Filling material | Liquid with good liquidity |

| Number of nozzles | 6,8,10,12,14,16 |

| Product Keywords | time gravity liquid filling machine |

Quick Details

Type: Filling Machine

Condition: New

Application: Chemical, Food, Medical

Packaging Type: Bottles

Packaging Material: Glass, Plastic

Automatic Grade: Automatic

Driven Type: Pneumatic

Voltage: 220V

Power: 3KW

Place of Origin: Shanghai, China (Mainland)

Brand Name: VKPAK

Dimension(L*W*H): Depends on detailed model

Weight: 250KG

Certification: ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Material: SUS304/316/PP

Function: Liquid filling

Warranty: 1 year

Filling theory: Gravity

Production capacity: 20-40BPM

Model: AGF

Bottle type: Hard PET bottle and glass bottle

Filling range: <1000ml

Filling material: Liquid with good liquidity

Number of nozzles: 6,8,10,12,14,16