Liquid Filling Machine

VKPAK manufactures a range of standard liquid filling machines to suit a wide variety of liquids, bottle sizes and production outputs. For businesses ranging from SME’s through to large multinationals, our machines can be used for a wide spectrum of applications.

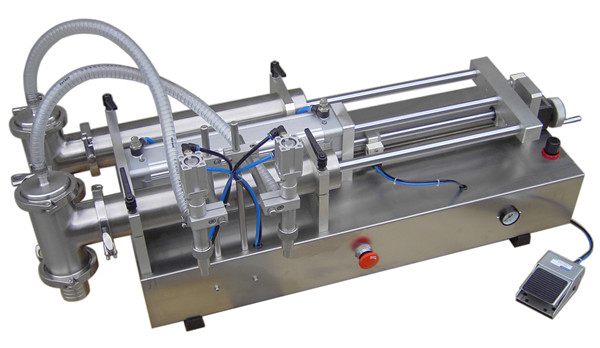

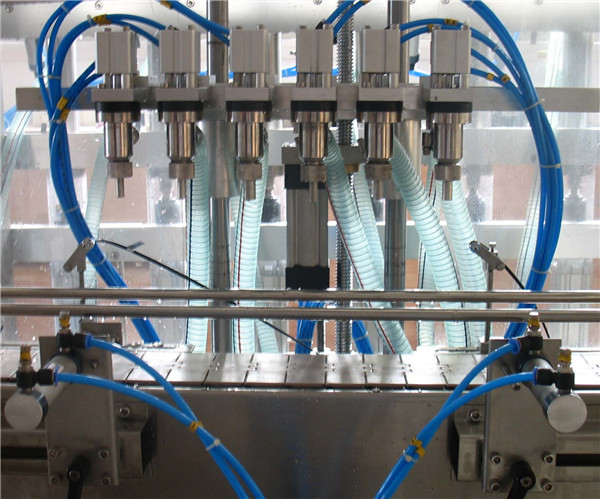

Our liquid filling machines range from simple single-head manually operated filling machines, through to fully automated multi-head filling systems using either vacuum level filling or volumetric piston filling technologies. If you cannot find a suitable machine in our standard range, please contact us to discuss your individual requirements – our engineering team is on hand to discuss modifications or even bespoke machine design solutions.

With over 20 years in business and a worldwide client base, we are proud to say that nearly 60% of our orders are repeat business from existing customers, who rely on VKPAK to provide them with first class support and help them grow their businesses.

VKPAK is the leading provider of inline liquid filling machines and liquid packaging machinery, offering a wide variety of fillers with manual, semi-automatic and fully automatic functions. We have both gravimetric and volumetric liquid fillers available for various industries from food and beverage production to industrial and corrosive product production.

Gravity and Pressure Fillers

The Gravity and Pressure/Gravity Fillers are suitable for bottling virtually any water-thin to medium consistent viscosity liquid. Gravity fillers are ideally suited for thin, foamy products where pressure/gravity fillers handle heavier viscosity products.

Pump Fillers

VKPAK offers several different types of pump fillers to accommodate a wide variety of products. They provide an accurate and versatile method for filling low, medium and high viscosity liquids into a wide range of containers. E-PAK uses a variety of pumps including progressive cavity pumps, gear pumps, lobe pumps, rotor pumps or whichever is best for the application. We work with each customer to choose the right pumps, valves, and fittings for each application.

Gravity, Pressure & Vacuum Overflow Bottle Fillers

Overflow Fillers provide the same cosmetic fill level, making them ideal for filling transparent containers that must have a consistent fill level. Gravity and pressure overflow fillers are designed to handle thin to medium viscosity products. The E-PAK Vacuum Overflow Filler is used for specialty filling applications and is typically used to fill small volume glass containers with low viscosity liquids.

Piston Filling Machine

Piston fillers are another great option for packaging liquids. They offer fast and accurate fill rates, versatility with the ability to handle many different types of products, and they’re gentle on products. They’re ideal for viscous liquids including batters, sauces, pastes, icing, chunky fillings, and certain aerated products. Generally, these liquid packing machines are used to fill liquids that are squeezed through pastry bags or similar packaging.

Net Weigh Liquid Fillers

Net weigh liquid filling systems are great for making sure that each container you fill contains the same amount of product. They are particularly efficient at packaging bulk quantities of products, along with products that are of high value and require the maximum accuracy when weighing them to avoid lost profits.

Liquid filling machines are used in many industries. VKPAK will help you make the right choice of liquid fillers based on the applications, production characteristics, and liquid filler performance objectives. VKPAK leads the liquid filling machine industry with the most innovative and best performing inline liquid filling systems.

Our automatic filling machines range in size from portable table top machines to industrial size liquid packaging systems – whatever is needed to get your job done. Don’t hesitate to contact us for more information on our products.