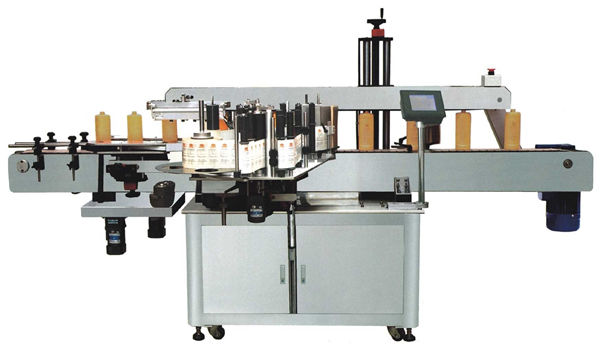

Round Bottle Labeling Machine

High-grade and energy efficient round bottle labeling machine is required for all kinds of cylindrical, tapered objects wrap around labeling. They are used largely in food, cosmetics, chemical, pharmaceutical and different other industry verticals. They come with a gamut of added features. You have to choose the right make and model and place your order.

Imported intelligent high-accuracy magic eye and high reliable Computer chip program controller(PLC)control the label and the case, label, using rubber roller pinned bottle the non-drying label followed the bottle in the bottle and put on rotating.

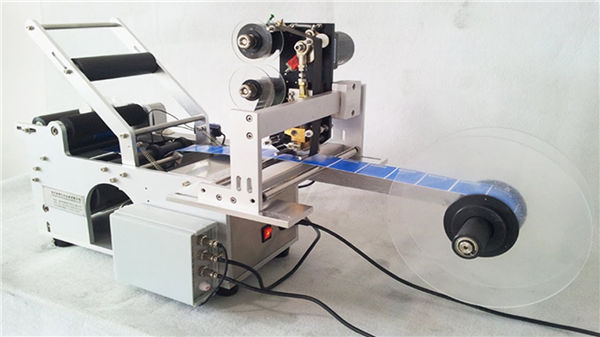

Apply label:

For non-clear adhesive label or pressure-sensitive label

Max standard label: (W)100 mm (or approx. 4 inches) (L)300 mm (or approx. 12 inches)

Inner label roll: 75mm (or approx. 3 inches)

Max outer label roll: 300mm (or approx. 12 inches)

Control System:

Program by microprocessor board, only one board with easy maintenance

Digital labeling parameters: start delay, peel length (and peeling speed , if no encoder)

Applicator switch

Wrap station:

Sponge belt driven by speed control motor

Applicator synchronized by encoder

Bottle diameter adjustment