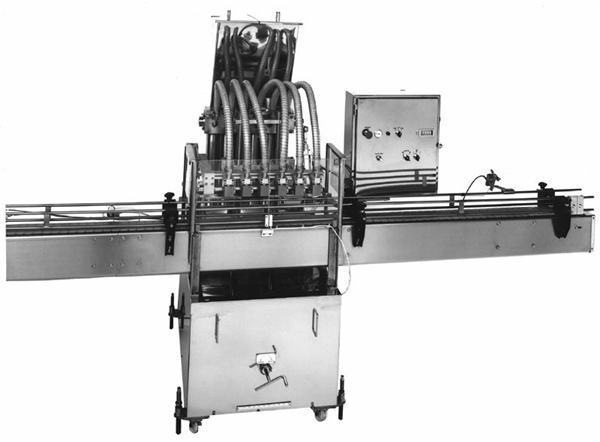

This machine adopts piston filling, it is suitable for viscous, low viscous and high viscous material at the same time.

The piston filling system of this machine could achieve bottle inlet counting, ration filling, bottle output etc automatically. It suits for high viscous material such as jam, wood floor wax care, engine oil, edible oil etc ration filling.

Technological parameters

| NO. | Items | Performance |

| 01 | Filling heads | 8 10 12 16 |

| 02 | Filling range | 50ml-1000ml (can be customized) |

| 03 | Diameter of bottle mouth | ≥Ø18mm ( can be customized) |

| 04 | Production capacity | 1000-6000bottles/hour (take 500ml foamy product as test) |

| 05 | Error range | time gravity filling error range: 1% |

| Piston filling error range: ±3g | ||

| 06 | Power supply | AC380V; 50Hz |

| 07 | Machine dinmension | 2400mm(L) x 1200mm(W) x 2500mm(H) |

| 08 | Air consumption | 0.55-0.65 Mpa clean and stable compressed air |

Suitable products

♦ Servo motor driving

♦ Control system - with PLC control system, filling dose is of random fine-tuning.

♦ Operation Interface - 6-inch color touch-style user interface, intuitive and simple, safe and reliable

♦ Feature Enhancements - Cutting with anti-drip device, it can dive to fill with functional properties of materials. (This feature can be optional)

♦ Electrical components - using internationally renowned brands to ensure that equipment’s reliability and high accuracy;

♦ Mechanical components - the contact parts are made of high quality stainless steel 316 and non-toxic corrosion and PTFE hoses. Other machine parts are made of high quality stainless steel 304.

♦ Count testing - real-time count, reflecting on the work output directly.

♦ Filling Detection - No bottle, or when bottles are not enough, no filling.

♦ Maintenance situations - the machine meets the GMP requirements, easy to disassemble, clean and maintain.

♦ Exchange standard – when changing filling specifications, you only need some simple adjusting to make it.

♦ Environmental protection configuration – the environmental framework in the machine makes operating environment more hygienic.

| 1 | Speed | 4000-5000bottles/h |

| 2 | Filling range | 50~1000ml |

| 3 | Measurement precision | ±1% |

| 4 | Working power | 220VAC |

| 5 | Air pressure | 6~7KG/CM² |

| 6 | Air consumpation | 1m³/min |

| 7 | Power rate | 0.8kw |

| 8 | Other devices power rate | 7.5kw(air compressor) |

| 9 | Net weight | 2520KG |

| 10 | Counter size | 2400X1500X2500mm |

Our Services

1. Installation, training and start-up by Our Factory Service Engineer is available.

2. With ZHONGTAI’s service engineers, you can feel confident in our professional knowledge and years of experience. If you have any service request, spare parts ordering, or other questions, please contact us.

3. We always send our service engineers to customer's factory to install and adjust machine, at the same time our engineers will train the workers of client and teach them knowledge about management machine, if our engineers stay 7days, it’s free to charge salary. But if more 7 days, customer pays our engineers one people one day usd50/person.

4. The customer pays the travelling expenses, food, and accommodation. We welcome clients send their workers to our company study. It's free to study machine on our factory, Our Company is charged with the fee of food and accommodation. Our machines are very easy to operate and manage. Worker can operate and manage these machines after they study three days. The number of persons training is as customer requirement.

Quick Details

Type: Filling Machine

Condition: New

Application: Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical

Packaging Type: Barrel, Bottles, Cans, Cartons, Case

Packaging Material: Glass, Metal, Plastic

Automatic Grade: Automatic

Driven Type: Electric

Voltage: AC380V 50/60HZ

Power: 2.5KW

Place of Origin: Shanghai, China (Mainland)

Brand Name: VKPAK

Dimension(L*W*H): 2400mm*1300mm*2150mm

Weight: 1200KG

Certification: SGS CE ISO

After-sales Service Provided: Engineers available to service machinery overseas

Machine body material: Stainless steel 304

Contact material: Stainless steel 316