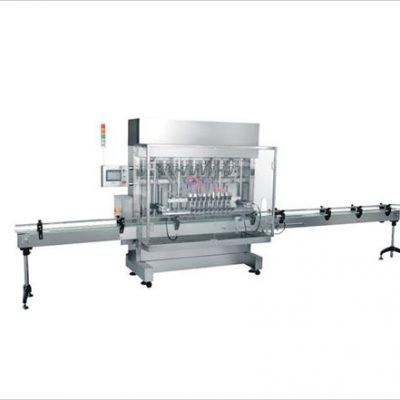

Introduction of semi-automatic thick-sauce filling machine:

This series of filling machine is a new division which is developed bu our own company according to the advanced foreign technology. Using piston-type metering principles, combining electrical with pneumatic function together, it performs many advantages,such as, reasonable design, compact structure, stable and reliable performance, accurate measurement, lightweight and flexiblity, good adaptablity, being easy to use and so on. This series of filling machine mainly consists of two species: Single-head and Double-headed (The non-calibrated products of multiple-head could be customed.). In order to meet different customers’ needs, each species can also be made into several patterns: vertical filling machine or horizontal one, and floor-standing one or desktop one, and filling machine’s drums with stirring or without stirring ...and so on,.

Electrical components and pneumatic components of the standarded series comes from the Japan’s Omron, and Taiwan’s Airtec respectively. If requested, German’s FESTO or Japan’s SMC pneumatic components could aslo be supplied. After the special treatment, This series of products’ piston cylinder, piston, seals and other parts can be applicable for high-temperature 80-98 temperature filling. It is widely used in a variety of viscous materials, semi-fluid, paste, sauces, especially the granule-containing materials filling and a variety of filling volume are provided to choose from.

Features of this series of filling machine

1.The body of machine are mainly made by the high-quality stainless steel and aluminum production, so they are very beautiful and sanitatary and in full compliance with food hygiene requirements;

2.They canbe operated by hands or automatically. With manual and automatic continuous filling function. And manual operation and automatic operationing can be switched quickly;

3.Fast connection makes dismantling, assembling and cleaning more convenient.

4.Electrical and pneumatic components are imported products, which has stable and reliable performance and excellent quality;

5.With several available anti-drip filling-heads, they are lightweight, convenient, and highly adaptive.

Semi-automatic thick-sauce filling machine mainly applies to fill the following materials

1.A variety of particles with or without semi-fluid granular, paste, viscous materials, such as various types of cream, syrup, containingfruit drinks, honey, etc.;

2.A variety of food sauces, all kinds of hot pepper sauce, jam, peanut butter, sesame, tomato paste and so on.

Main technical parameter

Filling range | Filling speed | Air consumption | Air source and Power | Filling accuracy | Remarks |

5-60ml | 10-35(bot)/min | 20L/min | (Air source) 0.4-0.6Mpa (Power) 220V/50HZ (Power) 10W | within)±1.5% | 1. The filling speed may be different because of the different materials. 2.The air consumption is measured by the speed of 10 bottles/min. 3.The mixing system can be installed inside in the drums of machine. |

20-100ml | 10-30(bot)/min | 25L/min | |||

50-200ml | 10-30(bot)/min | 30L/min | |||

100-500ml | 5-20(bot)/min | 45L/min | |||

300-1000ml | 5-20(bot)/min | 110L/min | |||

500-2000ml | 5-15(bot)/min | 230L/min |

Quick Details

Type: Filling Machine

Condition: New

Application: Beverage, Chemical, Food, Medical, Food catsup, liquid and semi-liquid

Packaging Type: Bottles

Packaging Material: Wood

Automatic Grade: Semi-Automatic

Driven Type: Pneumatic

Voltage: 220V/380V/110V

Power: 0.01kw

Place of Origin: Shanghai, China (Mainland)

Brand Name:VKPAK

Dimension(L*W*H): 1320x720x1520mm

Weight: about 100KG

After-sales Service Provided: Engineers available to service machinery overseas